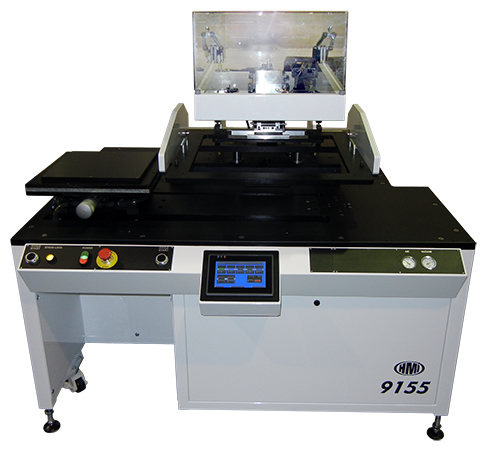

MSP-9155 Semi-Automatic Screen Printer

High-Volume Production & Substrates Up to 16" x 16"

A production printer capable of printing substrates or boards up to 16" x 16" (406mm x 406mm). A flexible production printer mounted in a rectangular frame with a reciprocating substrate carriage.

| Machine Dimensions (W x D x H) | 58” x 58” x 60” (1.48m x 1.48m x 1.53m) |

| Machine Weight (Approximate) | 1150 lb (525kg) |

| Controls | Industrial PLC |

| Vision Alignment | Manual |

| Print Head | Mark III Torsion bar squeegee head See other options |

| Squeegee Drive | Aqueous, closed system |

| Substrate Transport | Reciprocating workholder carriage |

| Screen/Substrate Alignment Method | Manual screen; Independent micrometers for X, Y; independent true Ø adjustment with dial indicator readout |

| Carriage Position Repeatability | ±0.0002" (±0.005mm) |

| Screen Position Adjustment | N/A |

| Screen Frame Attachment | Bolt-on |

| Operator Interface | Color touchscreen |

| Configuration | Standalone or automated |

Maximum Print Capabilities

| Maximum Screen Size (ID): | 20” x 20” (508mm x 508mm) |

| Maximum Substrate Size: | 16” x 16” (406mm x 406mm) |

| Maximum Print Area: | 16” x 16” (406mm x 406mm) |

Compare to Similar Models

| MSP-9155 | MSP-9155PC | MSP-9156 | |

|---|---|---|---|

| Maximum Screen Size (ID) | 20” x 20” (508mm x 508mm) | 20” x 20” (508mm x 508mm) | 20" x 20" (508 mm x 508 mm) |

| Maximum Substrate Size | 16” x 16” (406mm x 406mm) | 16” x 16” (406mm x 406mm) | 16" x 16" (406 mm x 406 mm) |

| Maximum Print Area | 16” x 16” (406mm x 406mm) | 16” x 16” (406mm x 406mm) | 16" x 16" (406 mm x 406 mm) |

| Machine Dimensions (W x D x H) | 58” x 58” x 60” (1.48m x 1.48m x 1.53m) | 58” x 58” x 60” (1.48m x 1.48m x 1.53m) | 58” x 58” x 60” (1.48m x 1.48m x 1.53m) |

| Machine Weight (Approximate) | 1150 lb (525kg) | 1150 lb (525kg) | 1150 lb (525kg) |

| Vision Alignment | Manual | Manual | Automatic alignment |

| Operator Interface | Color touchscreen | GUI, computer keyboard and monitor | GUI, computer keyboard and monitor |

| Request a Quote | See Product | See Product |

Request a Quote

To speak with an expert about a solution for your specific needs, call (908) 722-7100, email us directly at sales@hmiprinters.com, or send us a message using the form below.

Hary Manufacturing Inc.

Lebanon, NJ 08833

(908) 722.7100