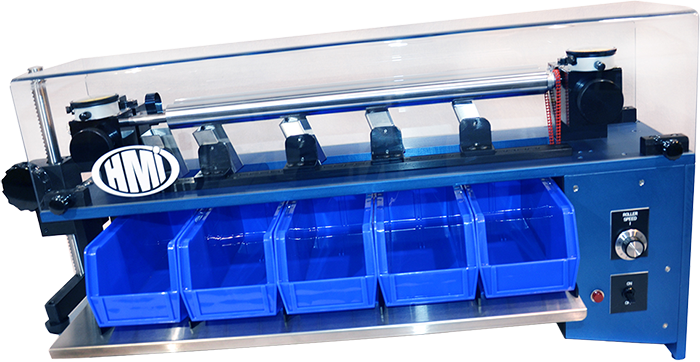

The HMI roller micrometer is used to sort small parts by size, quickly and accurately, prior to production and processing. Functioning like a continuous thickness gauge, the roller micrometer is an efficient solution for sizing and sorting a range of parts up to 0.5" in size, including:

- Solder spheres

- Bearings (steel/plastic/composite)

- Metal stampings

- Solder pre-forms

- Tungsten carbide forms

- Washers and metal studs

- Ceramic tubes

- Glass beads

Easily integrated into a cost-effective automation process with a simple feed mechanism, HMI roller micrometers function simply and precisely to size and sort a variety of parts with tolerances as close as 0.0001" ± 0.00001" (2.54µm ± 0.25µm) without special gauge blocks or procedures.

HMI roller micrometers are constructed with two precision-machined, highly polished rollers. The rollers are mounted parallel and level with one another, rotating upward and outward at the point where parts are introduced. Adjustable legs permit operation in a tilted position, so parts move down the incline between the rollers. In addition, one of the rollers is adjustable at one end, which creates a wedge-shaped opening. This opening allows parts introduced into the micrometer to fall through at different places, depending upon their diameter or dimension. Sorted parts are then caught in collectors, and are ready for use.

Hary Manufacturing Inc.

Lebanon, NJ 08833

(908) 722.7100